Whether you are working with a lathe, milling machine, or CNC chuck, you will inevitably encounter two common types of jaws: soft jaws and hard jaws. Many machinists are unsure about the differences between them. When should you use soft jaws, and when are hard jaws the better choice?

This article explains what soft jaws and hard jaws are, compares their key characteristics, and outlines their typical applications. By understanding the strengths of each option, you can choose the most suitable jaws for your machining tasks, improving both efficiency and product quality.

What Are Soft Jaws?

Soft jaws are machinable and customizable chuck jaws commonly used for workholding applications that require high positioning accuracy or the secure clamping of specially shaped parts. They are typically made from softer materials such as low-carbon steel, aluminum, or plastics, which allows machinists to machine the gripping surfaces directly on a CNC lathe or milling machine to match the exact contour of the workpiece.

Soft jaws are machinable and customizable chuck jaws commonly used for workholding applications that require high positioning accuracy or the secure clamping of specially shaped parts. They are typically made from softer materials such as low-carbon steel, aluminum, or plastics, which allows machinists to machine the gripping surfaces directly on a CNC lathe or milling machine to match the exact contour of the workpiece.

Many CNC chuck systems allow operators to easily swap different sets of soft jaws for various workpieces, significantly improving machining efficiency and repeatability in production. Although soft jaws generally have a shorter service life than hard jaws due to their softer material, their flexibility and re-machinability make them indispensable for precision machining and low-volume or custom production runs.

What Are Hard Jaws?

Hard jaws are among the most common standard workholding components in industrial machining, primarily used in scenarios requiring high clamping force or repetitive mass production.

Hard jaws are among the most common standard workholding components in industrial machining, primarily used in scenarios requiring high clamping force or repetitive mass production.

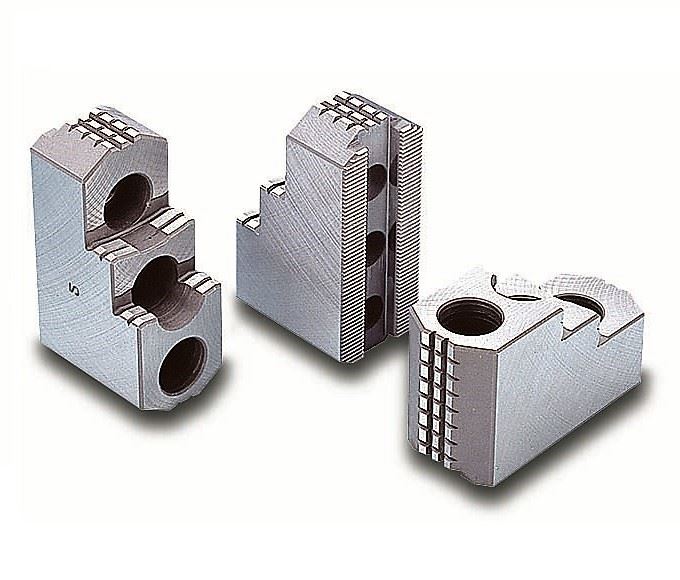

Typically manufactured from heat-treated alloy steel or tool steel, hard jaws boast high surface hardness and excellent wear resistance. This durability allows them to maintain consistent clamping force over long periods without deforming.

Hard jaws are generally designed with stepped gripping surfaces or serrated teeth that securely bite into the workpiece. This makes them particularly suitable for rough machining, heavy-duty cutting, or high-volume automated production processes, ensuring safety and stability throughout the operation.

Soft Jaws vs. Hard Jaws: Key Differences

With a clear understanding of what soft and hard jaws are, the next step is to evaluate how they impact your machining precision, clamping stability, and overall production efficiency. The following comparison will help you determine which jaw type is right for your application:

-

Customizability

- Soft Jaws: Soft jaws offer a high level of customizability. Because they are made from softer materials, machinists can directly turn or mill the jaws on CNC machines to match the exact shape, size, or locating requirements of the workpiece. This allows the jaws to conform perfectly to the part geometry, ensuring stable clamping and excellent repeatability. For irregularly shaped parts, thin-walled components, or precision parts where surface damage must be avoided, soft jaws can be re-machined to achieve an optimal fit.

- Hard Jaws: Hard jaws are standard, fixed-shape components. Due to their heat-treated, high-hardness materials, they are generally not machinable or modifiable and must be used as manufactured, with predefined dimensions and serration profiles. While this limits customization, it ensures consistent clamping force and dimensional stability over long-term use. Because of their exceptional wear resistance, hard jaws can withstand thousands of repetitive clamping cycles without deforming or losing accuracy. This makes them especially suitable for high-volume machining environments, where maintaining a consistent production rhythm and minimizing downtime for jaw replacement is critical.

-

Concentricity & Accuracy

- Soft Jaws: Because soft jaws can be machined to match the exact geometry of the workpiece, the gripping surfaces can achieve near-perfect contact with the part. This minimizes eccentricity and slippage during clamping, resulting in excellent concentricity and repeatable positioning accuracy. Soft jaws are particularly effective for finishing operations or secondary processes (OP20), where reducing runout and vibration is critical to achieving a stable surface finish and tight dimensional tolerances.

- Hard Jaws: Hard jaws rely on fixed serrated gripping surfaces, which typically provide only partial contact with the workpiece. Over time, wear on the serrations or deformation caused by repeated clamping can gradually reduce concentricity. In addition, the higher clamping forces applied by hard jaws may cause slight deformation in thin-walled or precision components, making it more difficult to maintain consistent accuracy over extended production runs.

-

Clamping Pressure

- Soft Jaws: Because the gripping surfaces of soft jaws are machined to match the workpiece geometry, they provide a large contact area during clamping. This allows the clamping force to be distributed evenly across the part surface. As a result, soft jaws can securely hold the workpiece even with relatively lower clamping pressure, reducing the risk of slippage or eccentricity.

- Hard Jaws: Hard jaws are designed for high rigidity and strong clamping force. Their gripping surfaces are typically serrated or stepped, resulting in point or line contact with the workpiece. To ensure secure holding, higher clamping pressure is often required. However, excessive pressure can lead to surface marks, indentation, or out-of-round conditions, especially when machining light metals or non-metallic materials.

-

Setup Time & Flexibility

- Soft Jaws: Soft jaws require a longer initial setup time because they must be machined to match the specific workpiece. Operators need to turn or mill the negative profile of the part into the jaws before clamping can begin. For the maximum clamping precision, the soft jaw should be re-finishing again once it reinstall on chuck.

- Hard Jaws: Hard jaws feature a standard, fixed design that is essentially ready-to-use. Since no additional machining is required, they offer rapid changeover speeds and broad versatility. In scenarios involving multiple part sizes, varied batches, or roughing operations, hard jaws significantly reduce preparation time and increase production line flexibility.

-

Workpiece Compatibility

- Soft Jaws: Soft jaws are ideal for thin-walled, easily distorted, or high-precision workpieces. Components such as thin-walled tubing, sleeves, motor housings, or bearing blocks can be held without deformation because the jaws are machined to create a custom, uniform gripping surface. Because they maintain a secure hold even at low clamping pressures, soft jaws are perfect for soft materials like aluminum, copper, and plastics. They are frequently used in OP20 (secondary operations) or final finishing stages to ensure strict dimensional tolerances and surface quality.

- Hard Jaws: Hard jaws are designed for rough machining and heavy-duty cutting. They can withstand high clamping pressures while maintaining rigid positioning, making them particularly effective for bar stock, forgings, thick-walled structures, or high-rigidity steel parts. Since these workpieces are resistant to deformation under pressure, hard jaws can fully leverage their high strength and durability. They are the go-to choice for roughing cuts, initial processing stages, and mass production workflows.

Summary Table – Soft Jaws vs. Hard Jaws

| Feature |

Soft Jaws |

Hard Jaws |

| Material |

Mild steel or aluminum; easy to machine. |

Hardened steel; very durable. |

| Customizability |

Machinable to match the part shape. |

Fixed shape, not customizable. |

| Accuracy |

High concentricity and repeatability. |

Lower precision after wear. |

| Clamping Pressure |

Low pressure needed; large contact area. |

High pressure required; small contact area. |

| Setup Time |

Longer setup, but highly precise. |

Quick change, very flexible. |

| Durability |

Softer, wears faster but reusable. |

Long lifespan, minimal maintenance. |

| Best For |

Thin-walled, soft, or precision parts. |

Heavy, rigid, or rough machining. |

Conclusion

Both soft jaws and hard jaws have their own advantages, and there is no absolute “better” option; the key lies in the specific machining requirements and workpiece characteristics. Knowing when and how to switch between soft jaws and hard jaws at different machining stages can significantly improve product quality while enhancing overall process efficiency and stability.

If you still have questions about choosing between soft jaws and hard jaws after reading this article, feel free to contact us for further consultation. All CHANDOX products are supplied with soft jaws as standard, and hard jaws are also available as optional accessories to meet different machining needs.